To add perspective to this thread, you can see my build thread here:

http://sharkcaver.blogspot.com.au/2016/04/x-marks-spot-development-of-nx-into.htmland check out my thread of why it all went tits up:

http://www.myswag.org/index.php?topic=49395.0So we are now back in business as below:

So,most will be aware of some hiccups in the suspension dept on my trip down the canning.

A week ago, I received some correspondence on how customer service should be handled. Its been a bit of a long saga, but Kudos to Dobinson Spring and Suspension, it looks like we have a winner. So here is what is being done:

The washers are now our normal style setup which has a 14mm pin, with a 15mm locating washer which slips over the pin to 18.5mm approx od to go in the 19mm hole with our regular syle bushes and washers (never had a problem with these ones previously and these are different to the ones you had on yours).

Issue one, taken note of and now sorted

The crimp is different. As mentioned, the hydraulic bloke says that the crimp should have held. This is the report he gave us and It should have held a lot more pressure and survived

Upon failure, they took it upon themselves to hire a professional hydraulic engineer to analyse the failure.

So it is evident they are serious about sorting this issue out. Whilst the analysis of the failure is open, all concerned agree it shouldn't have happened. So to cover any unforeseen contingencies, the crimp fitting has been changed to a type that should be even more durable.

Also mentioned was the fact that our mono’s had high valving because of the independent rear setup. We have since compared to others, and ours were higher so we have also lowered it down slightly. This will also keep them cooler (not that its a problem), and have less pressure build up in the hose.

I have been harping on since my return that although in this first instance we suffered failure, up to that point, the product proved to be superior. And as such, I hold the line that in conjunction with our results and their taking on board our issues, Dobinson is a force to be reckoned with and these MRR's will be kick ass and superior value for money for anyone that gives their vehicle a hard time in remote locations. And if it can handle those rigors, then imagine what they will do if not pushed as hard.

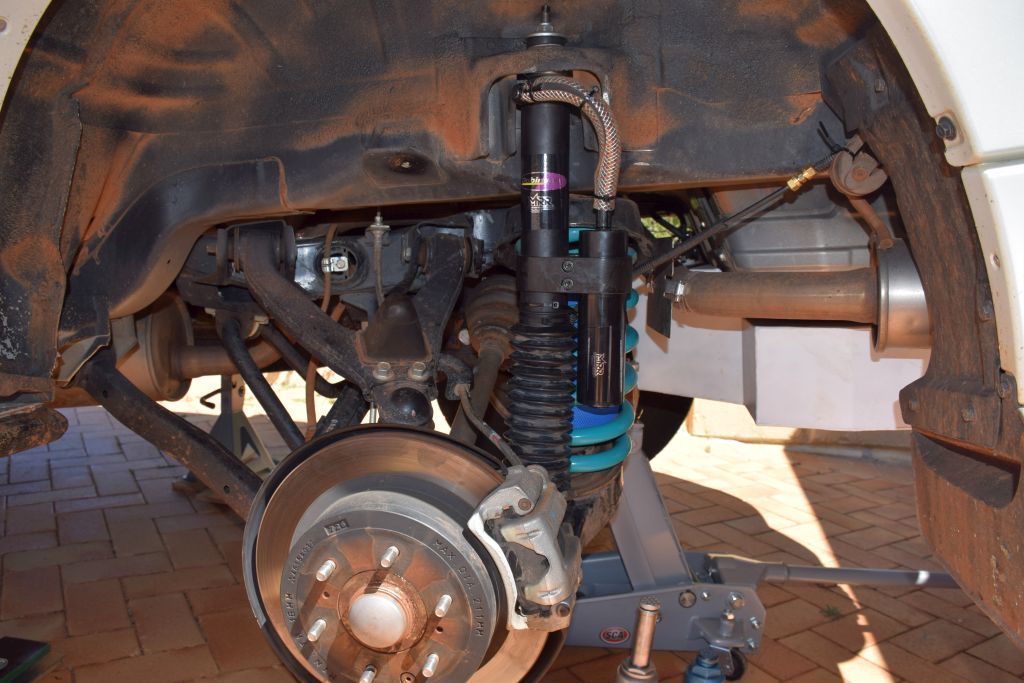

Today, I fitted these new shocks to the Paj:

And they were so much easier to compress than the last version. I could do these in the field, no worries.

New hoses, new Hydraulic crimp fittings and reduced valving should see that engineering issue taken care of.

The new locating washer should stop the shock from walking and cutting the rubber to bits on the top rubber cup:

The only issue though was this washer would not fit the existing mounting. The top cup seems to be very tight to remove, but the lower was not. So I removed the lower cup from the shock tower:

Set up the shock to suit and installed them:

Before i struck issues with the old, they were just running so well in the most arduous conditions. To compare, in the worst stretch of dirt, my mate with the same vehicle but different shocks, measured temps at 210 degrees. The Dobinson MRR was running at 105 degrees. So it goes without saying, these shocks were just performing so well that they had to be persevered with. And a big thanks goes to Dobinson for taking the time to listen to our issues, conduct the necessary engineering to sort them out, and to get us back on track. 100% support from a great Aussie company. I look forward to punishing them again, this time with renewed confidence.