I don't have a bench in my current shed, so dining room floor is close enough...

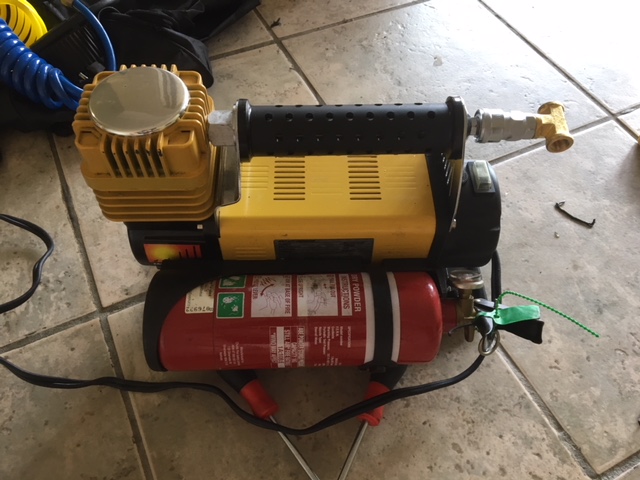

I've got a portable compressor that has been kicking around the car/shed for about 4 years now. Its a good sized one and if sat on the bench next to a lot of much more expensive units you'd be hard pressed to pick the difference. Some things I'm disappointed with are that that the cooling fins on the cylinder are some hard powder coated plastic, rather than aluminium, so as far as heat dissipation they do 4/5ths of bugger all.

The other is the carry bag it was supplied in, it's about as heavy duty as a $1 Woolies bag (I'm not talking about the insulated ones either) with the zip lasting about a month.

Last time I gave it a run it wasn't working as well as it should, so today I stripped it down to see what was wrong.

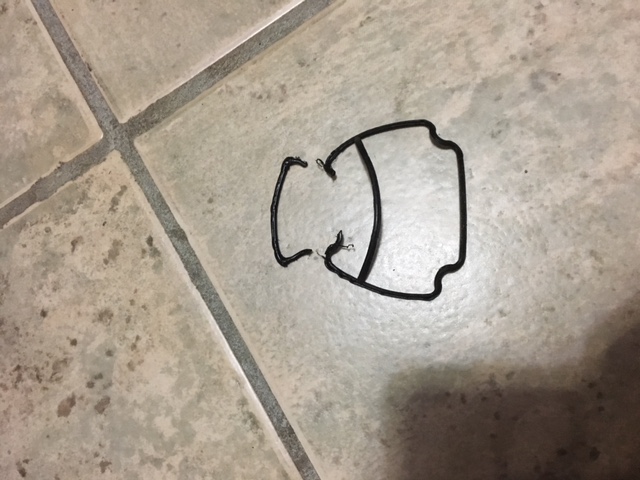

I pulled the head off to find that the screws holding it on were not much more than finger tight, the rubber gasket had blown out on one corner and one of the reed valves wasn't seating correctly. I flipped the reed valve over so it sat flat against the valve block, then cleaned up the valve block and head before replacing the blown seal with RTV. Right now its doing its 24hr cure and hopefully will work properly when I fire it up later.

Well, there's your problem!

So, the long term plan:

I had a small ARB compressor mounted in the back of the wagon that I wired up to a pressure switch, it worked really well. It would crank up to 110psi and shut off. I also fitted a tap at the end of the air hose, so switching between tyres the hose and the dinky little tank on the compressor would also be at 110psi, so I essentially had an 8L pressure tank. I wanted to do that again, but on a box I could shift between vehicles.

The plan for this one is to mount a T fitting on the outlet of the compressor, this had to be modified immediately as the Nitto outlet had some obscure thread on it that I couldn't match, so the male nitto copy was screwed back in and I stuck a female Nitto into the T and moved on. The other 2 outlets on the T will get a fitting for the air line and a pressure switch.

Its bulkier than I wanted, but will hopefully act as a heat sink. If the cheap ebay pressure switch or relay packs it in, then I can revert to the standard setup easily.

On the control circuit, power will come to a relay where I'll split it and run a wire to the pressure switch and use that to energise the relay. It will switch the compressor off when pressure reaches 110psi and on again when it drops to 90.

I've also got an old fire extinguisher that is probably due for replacement. The cylinder is rated to a constant 145psi with a test pressure of 290psi, so I don't think my setup will stress it too much.

I'll knock up an ally box to fit it all in to keep everything in one place and keep the sand and crap out of everything. I went berserk on eBay and bought more brass bits tonight, so a bit of waiting until I can finish it off. I'd like the convenience of getting the bits today, but 1 fitting was $11 at Supercheap and I can get the same for about $0.60 each online and I'm a tigharse

.

Ultimately I'd like one of these, but I'm struggling to justify the price. It would make things easy though, just like airing up at the servo.

Jamec Pem Digital Automatic Tyre Inflator.