Finally got the DRO scale fitted up to the lathe cross slide after all my thinking... took me 3 days on and off.

and with the cover removed

Rod I used to fit read outs to a lot of older machines. If no milled pads are present I would use square bits of 10mm plate (ground plate best ), drill four counter sinks to mount plate to the machine and three or four holes taped 3 or 4mm then use grub screws as jacks. Clock up the plates with a dial indicator until both within a couple of thou and mount the scales to that. Worked a treat every time.

Jimmy thanks I will do something like that on the X axis along the bed (hopefully tomorrow!). Should be easy!

The thinking was all about the cross slide which was tricky as it had to extend beyond the slide at the back.

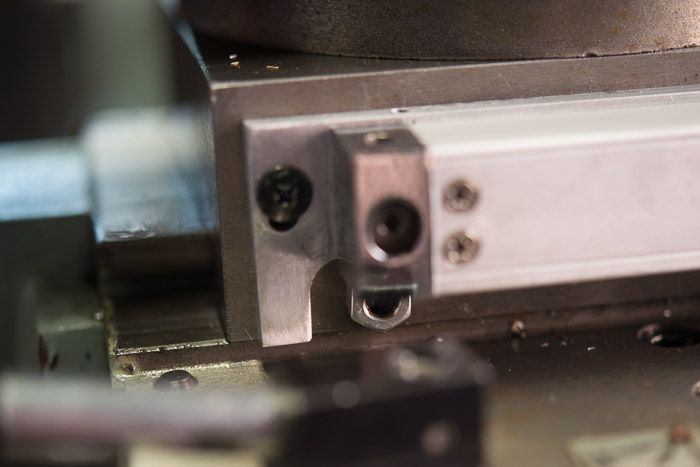

Started off with some 6mm Ally plate milled away to leave access to the gib screws.

drilled and tapped a couple of holes in the cross slide

countersunk one hole behind the scale so the scale would be flush with the mounting strip.

Front hole, is visible and I slotted the hole to allow adjustment to get the scale square (to 0.02mm which will do me!).

Milled up a block of ally to mount the sensor to the saddle.

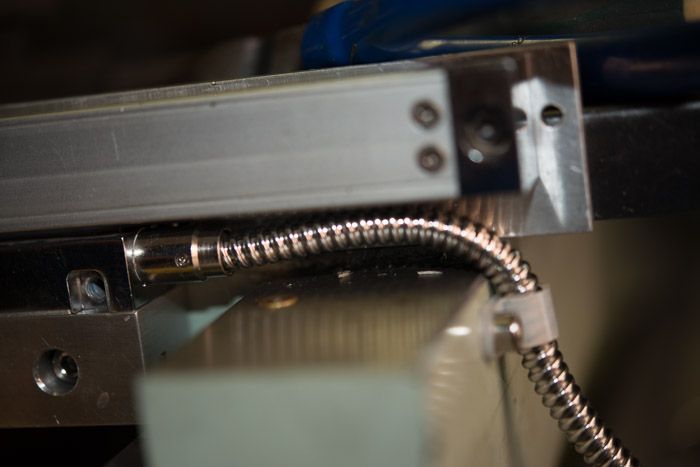

and tidied up the cable with another drilled and tapped hole in the saddle to mount a cable clamp

The covers have a mounting flange which I cut off and had to drill and tap 3mm holes in a 6mm wide piece of ally, but it all worked out good!

I would have liked to have used a coutersunk screw but the head would have overhung the mounting plate but it looks nice!

I had a bit of trouble getting the scale to work correctly as I had no adjustment on the sensor mount. But after adding a few shims and gentle cursing it is perfect!

I centrepunched the holes for the X axis scale but decided to be patient and tackle it in the morning when I am fresh!

EDIT: Ooops forgot to show you the readout