I made a start on the big anvil/vice this weekend.

I posted the threaded rod earlier so wont bother with that again but it uses a 1" acme thread for the main drive.

Scrap steel sorted.....

Before I got too excited I made the main drive mechanism. It uses thrust bearings either side of the shaft that gets welded to the moveable part of the vice.

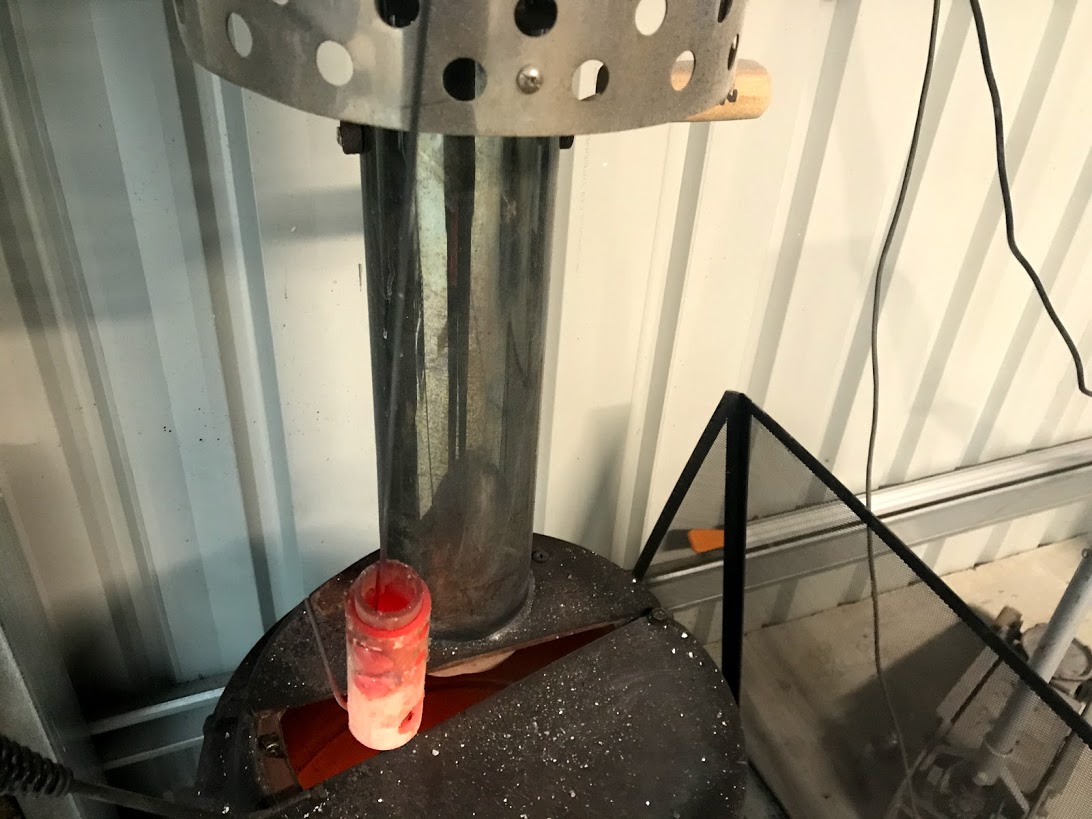

Who needs a furnace when you have a pot belly stove made from truck drums

Welded the huge nut (not me) to the base plate and made sure it will never want to pull forward!

Front plate to main channel

Now for some reason I forgot to take pics of the next process but it was a case of welding big chunky pieces of steel together to form an anvil and then shaping it to make it pretty.

Its far from finished but it is very solid and heavy. I have to weld the main anvil piece to the base and do some sanding to finish it.

I made a set of hardened steel clamp plates and I also made a set of soft alloy plates. I need to weld the alloy plates together yet as I want them to be 20mm thick. Ill leave the welds as welds and polish them for wank factor.

Ill get some better pics when I finish it, these are just the ones I had on my phone.

Oh and I made a stand for it.

The stand is also heavy duty....I filled it with concrete